Hydraulic fittings are components used to connect hoses, pipes, and tubes in a hydraulic system. They help contain and direct the flow of hydraulic fluid under pressure. There are several types of hydraulic fittings, categorized by connection type, shape, and sealing method:

1. By Connection Type:

a. Threaded Fittings

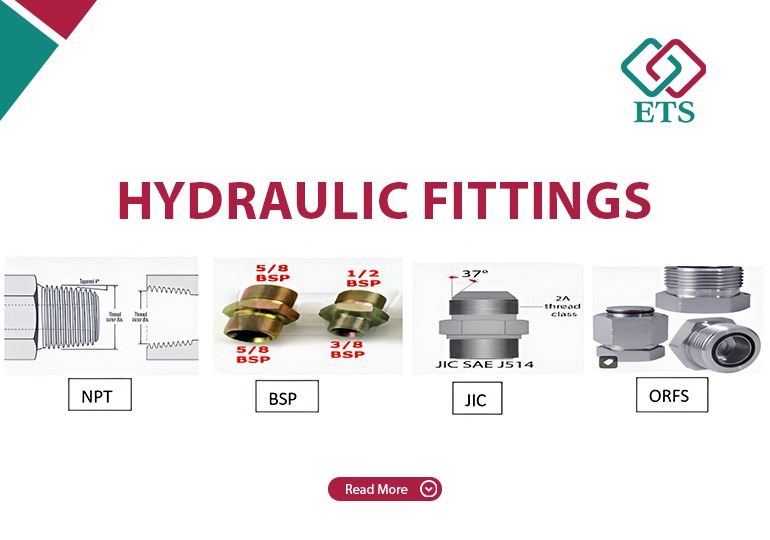

NPT (National Pipe Tapered): Common in North America; relies on thread tightness and sealant.

BSP (British Standard Pipe): Includes BSPT (tapered) and BSPP (parallel); common in Europe and Asia.

JIC (Joint Industry Council): 37° flare fitting, widely used in fluid power systems.

ORFS (O-Ring Face Seal): Provides a secure, leak-free seal using an O-ring in the face of the fitting.

SAE (Society of Automotive Engineers): Straight thread with O-ring; provides reliable sealing.

b. Flange Fittings

Used in high-pressure applications; includes split flanges or code 61/code 62 flanges.

c. Compression Fittings

Use a ferrule to compress against the pipe, ensuring a tight seal (e.g., DIN 2353).

d. Quick Disconnects (Quick Couplers)

Allow for fast connection/disconnection without tools; often used in mobile or temporary systems.

2. By Shape:

Straight

Elbow (45°, 90°)

Tee

Cross

Reducer

3. By Material:

Steel (high strength, used in industrial systems)

Stainless Steel (corrosion-resistant)

Brass (moderate strength, corrosion-resistant, often in lighter-duty systems)

Plastic/Composite (lower pressure applications)

4. Sealing Methods:

Metal-to-metal seal (e.g., JIC)

Elastomeric O-rings (e.g., ORFS, SAE)

Tapered thread seal (requires sealant or Teflon tape)